Page 405 - IRSEM_Main Book

P. 405

(d) Replacement of components of Axle Counters shall be done with utmost care

and as per technical manuals of OEMs. As a general rule, any maintenance

activities in track device area, like, ballast packing & rail changing etc. that

require disconnection of track devices and adjustments of axle counter

parameters shall not be done in working system. Where required,

maintenance staff shall take proper disconnection, duly de-energizing the

related sections of Axle Counters from CT rack/disconnection terminals

before starting indoor/outdoor maintenance activities. Once work is completed

the section should be connected/energised following all precautions related

to resetting, checking of parameters as stipulated and physical clearance of

track section before reconnection. Activities like measurement of

parameters, cleaning etc. which does not interfere with working of system,

may be carried without disconnection.

(e) Periodic preventive checks by maintenance staff shall be done to ensure

that track device/axle detector is properly fitted at site and fixing nuts/bolts

are properly tight and intact. Connections of track device cables are also

proper. Any damage/irregularity noticed in nuts/bolts/cables near the trackside

shall be immediately attended by duly disconnecting the associated track

section while attending the same for damages/irregularities.

(f) Wherever feasible, it is desirable to monitor working of axle counters

through Dataloggers with a suitable interface.

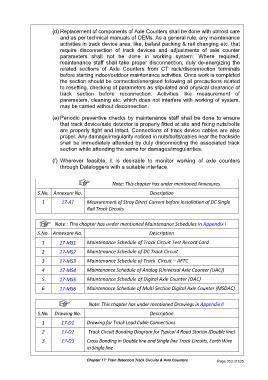

Note: This chapter has under mentioned Annexures

S.No. Annexure No. Description

1 17-A1 Measurement of Stray Direct Current before Installation of DC Single

Rail Track Circuits

Note : This chapter has under mentioned Maintenance Schedules in Appendix I

S.No. Annexure No. Description

1 17-MS1 Maintenance Schedule of Track Circuit Test Record Card

2 17-MS2 Maintenance Schedule of DC Track Circuit

3 17-MS3 Maintenance Schedule of Track Circuit – AFTC

4 17-MS4 Maintenance Schedule of Analog (Universal Axle Counter (UAC))

5 17-MS5 Maintenance Schedule of Digital Axle Counter (DAC)

6 17-MS6 Maintenance Schedule of Multi Section Digital Axle Counter (MSDAC)

Note: This chapter has under mentioned Drawings in Appendix II

S.No. Drawing No. Description

1 17-D1 Drawing for Track Lead Cable Connections

2 17-D2 Track Circuit Bonding Diagram for Typical 4 Road Station (Double line)

3 17-D3 Cross Bonding in Double line and Single line Track Circuits, Earth Wire

in Single line

Chapter 17: Train Detection Track Circuits & Axle Counters Page 353 of 535